Proposition de thèse 2024-2027

Sciences et Ingénierie de la Matière Molle (SIMM),

UMR 7615

Adresse : ESPCI – 10 rue Vauquelin – 75231 Paris Cedex 05

Directeur de l’Unité : Etienne Barthel

Supervisors to contact :

Jean Comtet ![]()

Costantino Creton ![]()

Industrially funded CIFRE PhD fellowship in collaboration with ESPCI / Michelin

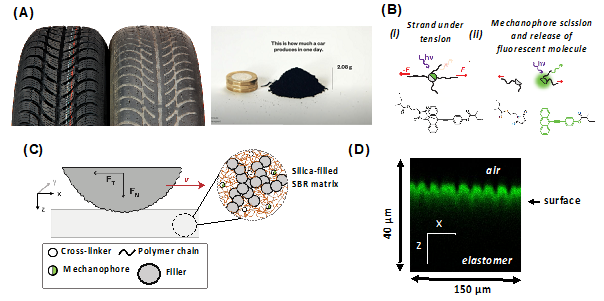

Figure 1. (A) Picture of new and worn tire (source: The Tyre Collective). (B) Mechanophore scission in the network to probe chain-breaking events (C) Reciprocal sliding of a rough glass bead on the elastomer network, composed of silica-filled SBR matrix. (D) Preliminary data showing cross-sectional fluorescence image of the near surface region of a wear mark, reconstructed from a confocal microscopy scan (material: multiple network elastomer).

Figure 1. (A) Picture of new and worn tire (source: The Tyre Collective). (B) Mechanophore scission in the network to probe chain-breaking events (C) Reciprocal sliding of a rough glass bead on the elastomer network, composed of silica-filled SBR matrix. (D) Preliminary data showing cross-sectional fluorescence image of the near surface region of a wear mark, reconstructed from a confocal microscopy scan (material: multiple network elastomer).

Associated with major environmental, safety and economic issues, tire wear is a critical challenge for the transportation and automotive industry (Fig. 1A). Gaining insights on the processes behind tire wear appears to be the first step towards the mitigation of this detrimental phenomena which might become even more pregnant with the on-going development and use of heavier electric vehicle.

Surprisingly, our fundamental understanding of the mechanisms through which elastomeric materials progressively wear off by mild friction with the road remains poor. This knowledge gap is due to our current inability to access the complex interactions between molecular damage accumulation and erosion processes at play at or near the tire/road frictional interface. Current experimental characterization of frictional wear is indeed mostly limited to descriptive and macroscopic approaches, such as visual description of the worn surface profile or measurements of weight loss.

Over the recent years, the host team at SIMM, ESPCI has developed original mechanochemical approaches to quantitatively map the molecular damage occurring through bond scission in soft elastomers [1-2]. Our strategy relies on the incorporation of a mechanophore molecule in the elastomeric network, which becomes fluorescent when a specific bond breaks, allowing for the robust, reliable and direct spatial quantification of the overwise undetectable chain damage in the material (Fig. 1B)

Building upon these state-of-the-art mechanochemical approaches, we aim through this PhD to reveal the key microscopic physical mechanisms at play during elastomer wear by friction. We will focus in particular on the so-called “fatigue wear” regime, whereby mild yet repeated frictional contacts of a rough indenter on the elastomer leads to damage accumulation below the surface, and ultimately to material loss [3-4]. These studies will be performed on nanocomposite materials composed a styrene butadiene rubber matrix reinforced with silica particles, which represent a good model system for engineering elastomers, and for which we have recently been able to extend our mechanochemical approaches. We will combine macroscopic measurements of mass loss following repeated friction cycles with microscopic quantification of mechanophore activation and subsurface molecular damage using confocal microscopy (Figs. 1 C-D). We will probe in particular, the role of the frictional contact - associated with cycle number, load, indenter roughness, temperature, speed or addition of an inorganic third body… - on macroscopic wear and on the extension of microscopic damage in the material. These measurements of molecular damage following complex frictional loading will be put in perspective with simpler cyclic fatigue test at various rates, temperature and cycle number, allowing for a precise determination of a damage accumulation law for the material.

By revealing previously invisible chain damage processes, our approach will reveal a new molecular picture of elastomer frictional wear and allow us to propose a quantitative scenario for frictional wear, coupling the complex frictional contact with molecular damage accumulation laws and material erosion processes. Ultimately, we expect that the predictive insights gained by this study will stimulate the development of safer and greener tire materials for a more sustainable transportation future.

This PhD is an industrially funded Cifre fellowship in partnership ESPCI / Michelin. Most of the PhD work will be carried out in the SIMM lab, ESPCI, Paris, but regular interactions with the industrial partner will take place as well as regular on-site short-term visits and experiments in Ladoux, Clermont-Ferrand. We are looking for a student, strongly motivated by this highly interdisciplinary PhD project, coupling material chemistry, soft matter physics, mechanics and optics.

Bibliography

[1] Slootman, J., Yeh, C. J., Millereau, P., Comtet, J., & Creton, C. (2022). A molecular interpretation of the toughness of multiple network elastomers at high temperature. Proceedings of the National Academy of Sciences, 119(13), e2116127119.

[2] Slootman, J., Waltz, V., Yeh, C. J., Baumann, C., Göstl, R., Comtet, J., & Creton, C. (2020). Quantifying rate-and temperature-dependent molecular damage in elastomer fracture. Physical Review X, 10(4), 041045.

[3] Sanoja, G. E., Morelle, X. P., Comtet, J., Yeh, C. J., Ciccotti, M., & Creton, C. (2021). Why is mechanical fatigue different from toughness in elastomers ? The role of damage by polymer chain scission. Science advances, 7(42), eabg9410.

[4] Moore, D. F. (1980). Friction and wear in rubbers and tyres. Wear, 61(2), 273-282.

[5] Schallamach, A. (1968). Abrasion, fatigue, and smearing of rubber. Journal of Applied Polymer Science, 12(2), 281-293.