Antoine Chateauminois, Christian Frétigny, Emilie Verneuil

Friction between solid interfaces arises from mechanisms involving length scales that span a wide range : interactions between molecules located at the interface (microscopic scale), between asperities due to the interfaces roughness (mesoscopic scale), deformation of the bulk material close to the interface (macroscopic scale). Friction also depends on the physico-chemical, geometric and mechanical characteristics of the interfaces. The couplings between these very different effects challenges the interpretation of the experiments from the sole material properties. Hence, the physics at stake in friction mechanisms still lacks a description at the fundamental level, which is however key for the optimization of numerous systems relevant to everyday-life applications.

The SIMM lab has been working for several years on the friction of elastomers and hydrogels, with a particular focus on the development of unique experimental set-ups aiming specifically at allowing for the advanced interpretation of experimental data in terms of molecular dynamics or material mechanics. We detail below the results of two studies where we explored the effects of the finite size of contacts and of the non-uniformity of the fields within the interface on transient friction.

Transient friction in finite size contacts: mechanical and geometrical non-uniformities

Memory effects in rubber friction

with V. Fazio and V. Acito

Collaboration with Hutchinson, Montargis and F. Amiot, FEMTO, Besançon

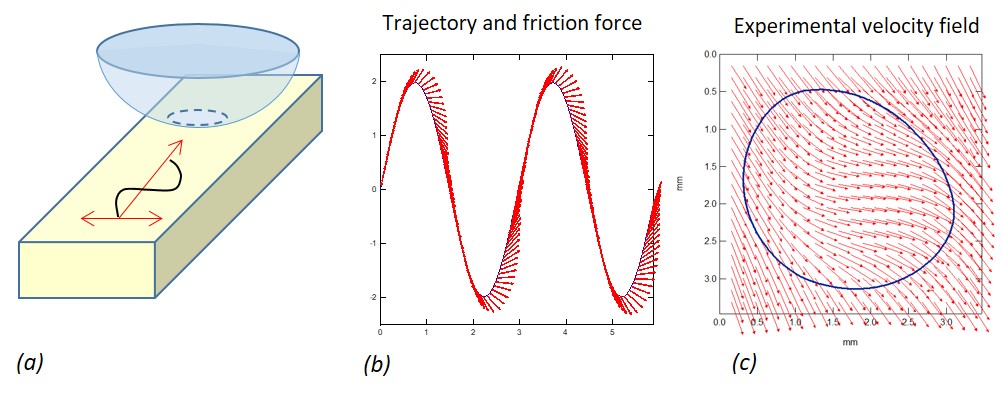

Transient frictional regimes have long been recognized to involve complex history effects which remains essentially described within the frame work of phenomenological models. In order to address the underlying physical mechanisms, we carry out friction experiments where the contact interface is perturbed by non rectilinear sliding trajectories. As an example, controlled transient friction is achieved by imposing a sinus wave motion to a spherical glass probe in contact with a plane rubber substrate, while measuring the two components of the friction force within the contact plane (Fig.a). We find that the friction force is not tangent to the trajectory (Fig.b) as a result of the non-uniform distribution of the sliding velocity within the contact interface (Fig.c)These observations are accounted for by a friction model which takes into account heterogeneous displacements within the contact area

(a) Contact between a rubber substrate and a spherical glass probe under sinus wave motions. (b) Red arrows : Orientation of the friction force along the imposed trajectory (blue line) (c) Red arrows : Sliding velocity field measured within and around the contact. Blue line : contact edge

References

V. Fazio, V. Acito, F. Amiot, C. Frétigny and A. Chateauminois, Memory effects in friction: the role of sliding heterogeneities, Proceedings of the Royal Society A 477 (2021) 20210559

Onset of sliding on thin hydrogel films: friction and poroelastic transport

With Jessica Delavoipière, Lola Ciapa and Yvette Tran

Collaboration Saint Gobain Recherche Paris

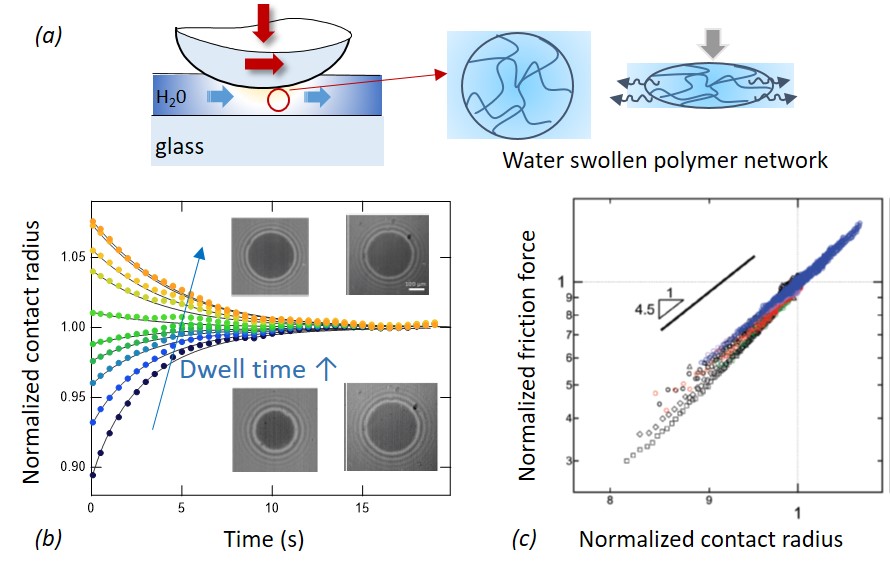

When a spherical glass sphere is pressed on a hydrogel thin film, the swollen network releases water and the resulting contact depends on the elastic properties of the polymer network (Fig.a). The drainage of water out of the contact zone is characterized by the so-called poroelastic time which depends also on the network permeability.

If now the sphere slides on the hydrogel, a transient regime is observed during which both the contact radius and the friction force adjust to the movement. By measuring the time variation of the contact radius and friction force at onset of sliding (Fig.b,c), we showed that the poroelastic flows entirely set the dynamics of the contact size, which was modelled within a thin film approximation. We also showed that the friction force is set by the contact area through a power law (Fig. c).

(a) Sliding of a spherical glass sphere on a thin hydrogel film (micrometer-thick). (b) During the onset of sliding, the contact size varies due to water transfers in the gel film under the contact. Depending on the dwell time, the onset of sliding causes either an incoming or an expelling flux and the contact size either decreases or increases. (c) The time variations of the friction force during the transient follow a power law variation with contact radius allowing to collapse all the data on a single master curve.

References

L. Ciapa, J. Delavoipière, Y. Tran, E. Verneuil, and A. Chateauminois, Transient sliding of thin hydrogel films : the role of poroelasticity, Soft Matter 16 (2020) 16, 6539

J. Delavoipière, Y. Tran, E. Verneuil, B. Herteufeu, C.-Y. Hui and A. Chateauminois, Friction of poroelastic contact with thin hydrogel layers, Langmuir 34 (2018) 9617-9626

J. Delavoipière, Y. Tran, E. Verneuil and A. Chateauminois, Poroelastic indentation of mechanically confined hydrogel layers, Soft Matter 12 (2016) 8049-8058

J. Delavoipière, B. Herteufeu, J. Teisseire, A. Chateauminois, Y. Tran, M. Fermigier and E. Verneuil

Swelling dynamics of surface-attached hydrogel thin films in vapor flows, Langmuir 34 (2018) 15238-15244