Proposition de thèse 2024-2027

Laboratoire Sciences et Ingénierie de la Matière Molle, (SIMM)

Adresse: ESPCI, 10 Rue Vauquelin 75005 Paris

Directeur du laboratoire: Etienne Barthel

Responsables du stage: Matteo Ciccotti (![]() ), Frédéric Lechenault (

), Frédéric Lechenault (![]() )

)

Context:

In fracture mechanics the energy required for crack propagation comes from both the work applied remotely and the release of elastic energy stored in the sample, yet extent and direction of crack propagation are free and emerge from the interplay of energy minimization and dissipation. In cutting, the work is applied locally through the tool and both the extent and direction of crack propagation are tentatively enforced by the motion of the blade [1].

A unifying physical view of cutting suitable for a large class of materials is still lacking, especially for soft materials. The standard tools of linear elastic fracture mechanics are not suited to treat a problem where the driving arises directly at the crack lips instead of remotely. The local crack fields are strongly coupled with the shape and motion of the blade, involving subtle adhesion and friction problems. In this context the fracture energy and direction of propagation are not independent of the shape of the blade and new tools have to be developed to describe them. Although the case of soft materials is of particular importance for many industrial applications, very few tools are available to deal with the very strong nonlinear deformations at different scales, which make it difficult to cut parts of the desired shape and with good surface finish.

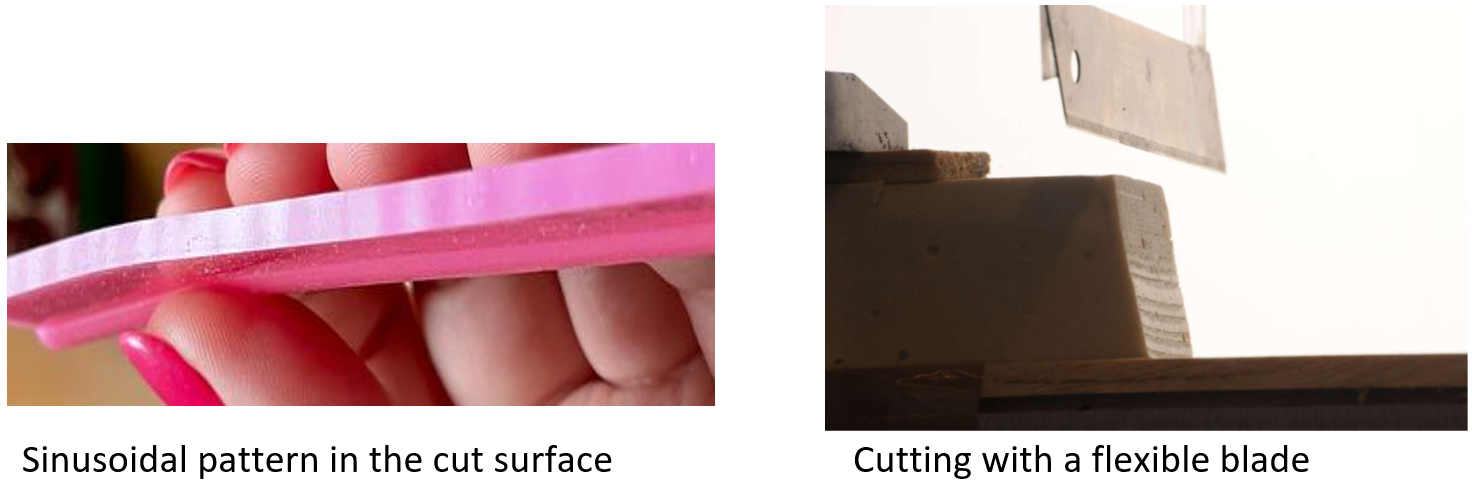

When cutting soft (and tough) materials, additional complexity emerges from the large strains experienced by the material during the cutting. On the one hand, the path can only be imposed in the deformed material and control is lost on the shape of the resulting cut surfaces (as seen in the figure). On the other hand, the constitutive response of soft materials to large strains can be very nonlinear and specific to each material [2].

The cutting process is thus a combination of contact, fracture, adhesion and friction with geometrical and material nonlinearities: six different sources of nonlinearities which are promising for both a rich morphogenesis and very erratic behaviors making experimentation very challenging

Objectives:

We plan to systematically investigate these phenomena experimentally by using a large range of materials, with variable stiffness/toughness, loading configurations, and the geometry/stiffness of custom sharpened blades [3]. We aim at developing a common theoretical framework to deal with our cutting of soft materials based on combination of fracture and contact mechanics tools, nonlinear and statistical physics to deal with the interplay of instabilities and heterogeneity. We aim at capitalizing on the achieved understanding to program the shape of the cut surfaces from custom loading of both the samples and the cutting tools.

References:

[1] T. Atkins. The Science and Engineering of Cutting (2009).

[2] C. Creton and M. Ciccotti. Fracture and adhesion of soft materials : a review, Reports on Progress in Physics, 79, Art N. 046601 (2016).

[3] F. Lechenault, I. Ramdane, S. Moulinet, M. Roman-Faure and M. Ciccotti. Soft coring: how to get a clarinet out of a flute? Extreme Mechanics Letters 61, 101976

Profile

Masters student, interested by experimental physics, with competencies in materials science, applied mechanics, image analysis.