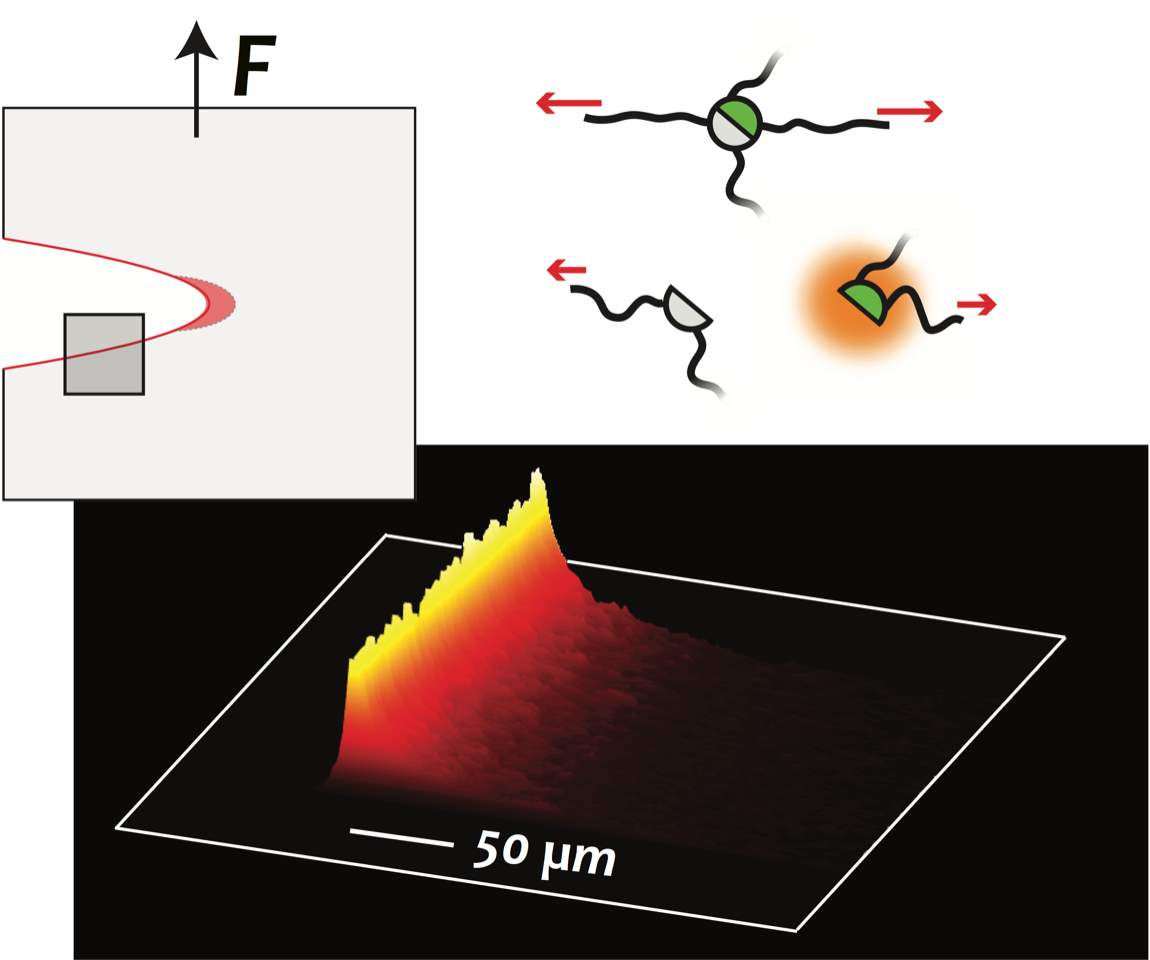

When rubbery materials (elastomers) are stretched, they typically extend elastically and spring back to their original shape. However, if stretched too far, they break into two pieces by the formation and propagation of a crack. Understanding why increasing the temperature or decreasing the rate at which the elastomer is deformed leads to a significant decrease of the stretch at which it breaks has been a challenge for the last 50 years, partly because the picture of molecular bond breakage was missing. To address this missing element, a team of researchers of SIMM, ESPCI and RWTH Aachen have used novel damage-sensitive fluorescent molecules incorporated in an elastomer network to visualize, quantify, and map the breakage of chemical bonds accompanying macroscopic fracture.

To their surprise, they found that the number of broken bonds near a crack is very strongly and almost linearly correlated to the level of molecular friction in the material. These observations contradict classical models of fracture, which assume a decoupling between a constant level of damage at the interface, and a purely viscoelastic over-dissipation in the material. On the contrary, these measurements evidence the occurence of intrinsically multi-scale processes between chain rupture and viscoelastic relaxation in the material, mediated by the local strains at the crack tip.

These results will likely stimulate new physics-based molecular models of elastomer fracture and guide the design of better fracture-resistant elastomers.

They are publish in Physical Review X [https://journals.aps.org/prx/abstract/10.1103/PhysRevX.10.041045]